Clark November 4th, 2016

Once I was buying a galvanic isolator in a West Marine store, when a West Marine employee, of all people, was really insistent that I shouldn’t buy it: “Those things are a scam! They don’t do anything. I have it on good authority that they’re a big waste of money!” He had that look in his eye, so rather than get all marine electrician on his ass, I just said, “Well, my customer wants it, so I think I’ll buy it all the same.” There are a lot of misconceptions about the purpose of a galvanic isolator, and what it can and can’t do.

Flash forward to this week when another friend/customer calls me down to his boat, says his zinc anodes are being eaten too quickly and he’s thinking about a galvanic isolator. When I get there he shows me a propeller shaft anode that a diver had replaced just over a week before, and it’s already over a third eaten. To get to that stage should take a few months.

A galvanic isolator will sometimes, but by no means always, solve the anode-eating problem. A galvanic isolator is installed in-line along the safety ground (grounding conductor, green wire) in the shore power connection, so of course if you’re not plugged into shore power at a dock, then you’re barking up the wrong tree.

My customer was plugged into shore power, but being a thorough guy I unplugged him from shore power and did a galvanic survey of all the underwater metal items on his boat using a reference cell, dangling in the water, connected to a digital multi-meter. All the numbers came up about right for a standard fiberglass boat, his bonding system was all intact, and he had the right amount of zinc anodes to protect his underwater metals.

But if we plugged in his shore power cord, his hull potential changed by about 200 millivolts. Aha, problem found, but people want to point to some AC problem, since this is coming from the AC shore power cord. Nay. Galvanic corrosion and stray current corrosion are caused by DC currents.

In fact, I could measure half an Amp of DC current by putting my Amp clamp, on the DC setting, around his shore power cord.

If your boat is bonded properly then all of the major metal parts, above and below water, are bonded together, usually using big green wire. It will also have an AC safety ground, also usually green wire, connecting all the AC outlets and appliances, just like at home. These two systems cross-connect at one, and only one, point. So, when you plug into shore power, your boat is connected, via the safety ground, to the safety ground system on every other boat on the dock, and thus to the bonding system and all the underwater metals, on every other boat on the dock. What could possibly go wrong?

My customer may have been doing everything right, but since his bonding system is connected to his AC safety ground system, and since his neighbors’ boats are the same, and since they’re all connected together via the AC safety ground wires in their shore power cords, his zinc anode was protecting his boat plus the boat next door, or maybe down the way, or maybe all the boats down the row. But even though it’s via the AC shore power cord, it’s galvanic corrosion, which means a DC current.

It could also be stray current current corrosion, that is, corrosion caused by an electrical current, but stray current is still a DC thing. AC current just doesn’t cause or accelerate corrosion in normal circumstances.

Whether his half an Amp of DC current came from pure galvanic action or stray current corrosion is beyond my pay grade. I tend to think the latter, because half an Amp is quite a bit. Maybe there’s no way to tell, but the solution, in any case, is a galvanic isolator.

A galvanic isolator blocks low level DC currents from traveling down the AC safety ground.

It doesn’t do anything about galvanic corrosion within the confines of the boat it’s on, thus the corrosion survey before zeroing in on the galvanic isolator. As a marine electrician, I think I had to go this route to rule out other causes beforehand. If I just slapped a galvanic isolator on there without poking around, I’d have to advise him to have his diver come back in another two weeks to check the anodes, and this would cost more than my additional poking around.

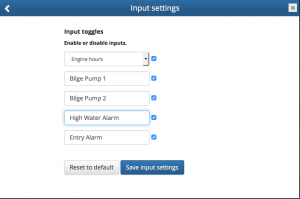

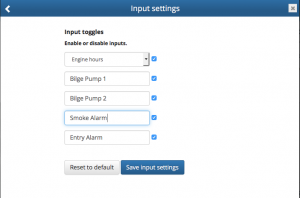

Before the galvanic isolator was installed:

And after:

Voila! But two days before I’d read .5 Amps, instead of .3 Amps. What changed? I don’t know, but .3 is still bad.

As a boat owner who is constantly/often plugged into shore power, should you just slap one on as a matter of course?: Yes

Will it solve your problem with fast anode depletion?: Probably maybe.

But even if you don’t have a problem now, you may in the future, as your fate is tied to all those other boats on the dock, so it’s good insurance. It’s especially good insurance when you compare the couple hundred bucks for the galvanic isolator to the financial ruin of a devoured prop and shaft, keel/keel bolts, outdrives, et al. It’s not just about saving anodes; it’s about saving what gets eaten after the anode is gone.

Likewise, it will not solve a stray current problem within your boat. If you’ve got nasty old exposed bilge pump wires sitting in the bilge water, you might just stray current your keel off.

And a galvanic islolator only protects against low level DC, up to 1.2 or 1.4 Volts, so if there’s some banzai stray current issue in your marina, which creates a voltage higher than that, the isolator won’t do anything, but this would be unusual.

It used to be that a galvanic isolator could fail, not only negating its anti-corrosion purpose, but creating a potentially deadly break in the AC safety ground. So after that they made it so you had to have a monitoring system that would warn you if its function was compromised. Now, galvanic isolators are fail safe, meaning that if they lose their anti-corrosion function they still maintain their AC safety ground function. They are still supposed to be tested annually. If you’ve got an older galvanic isolator, you should replace it with a fail safe.

There is a magic box called an isolation transformer that makes all of this go away, but isolation transformers are big, expensive, and heavy, so not practical for the average sailboat…unless your sailboat is steel or aluminum, in which case you should pony up and make the space.